Process-reliable heat treatment

This is how you can ensure a stable process with automated handling technology and improve your production.

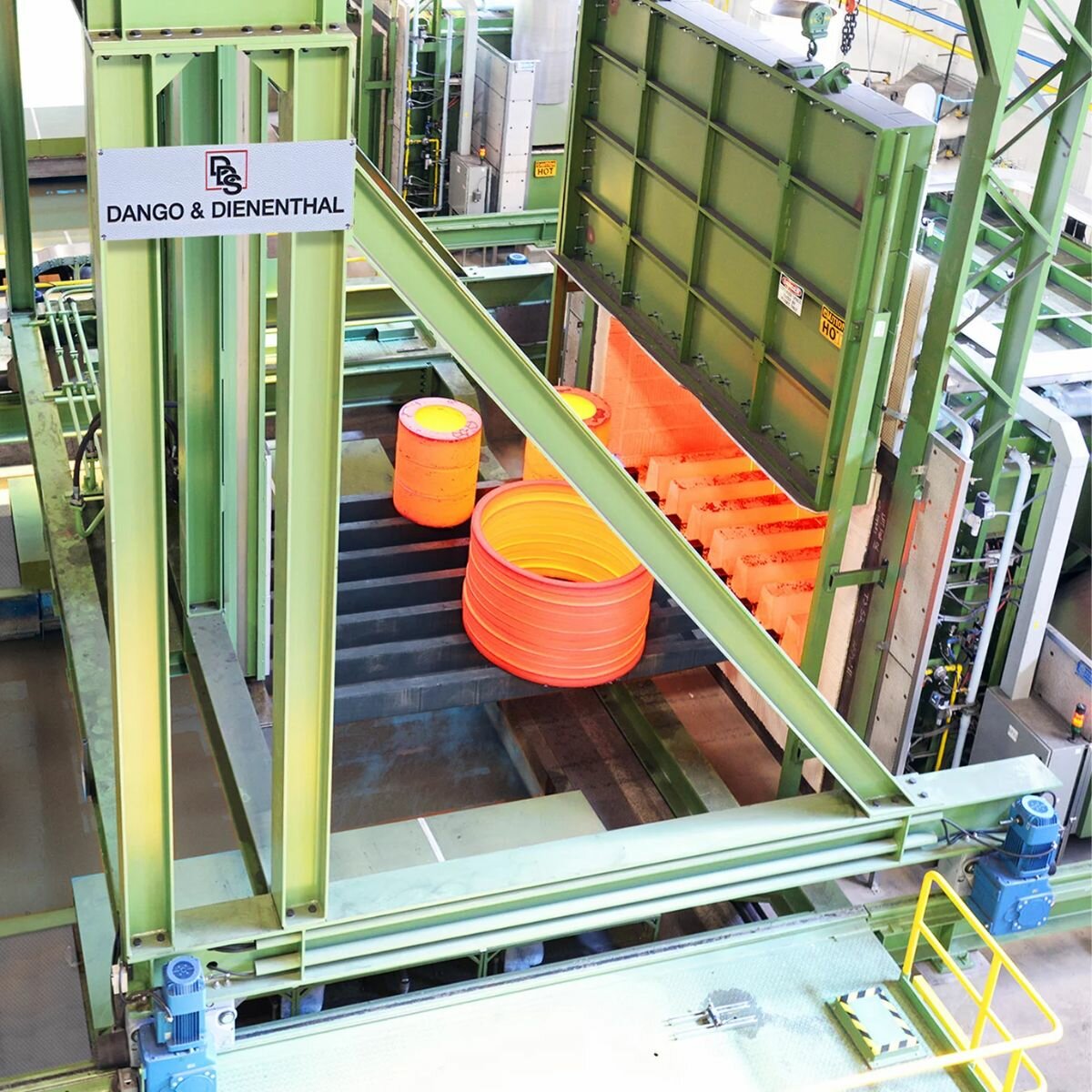

HEAT TREATMENT IN METAL PROCESSING

Many industries still rely on manual processes for heat treatment. However, traditional methods quickly reach their limits, especially with high temperatures, heavy workpieces and complex cycle times.

Inadequate material handling, outdated material handling equipment or non-ergonomic lifting aids lead to delays, safety risks and quality losses. Particularly when using high-performance industrial furnaces, well thought-out handling systems are crucial for stable processes and predictable results.

To the handling systems

WHAT IS HEAT TREATMENT?

Heat treatment is a thermal process that specifically influences the properties of metals - e.g. hardness, strength or toughness. Through controlled heating and cooling, the microstructure is changed to make components more efficient and durable. It is a central component of the metal processing industry.

AIMS OF HEAT TREATMENT

- Increasing hardness for better wear resistance

- Stress relief after forming or welding processes

- Microstructural changes for optimized material properties

- Improved toughness for dynamic loads

- Dimensional stability through targeted microstructure control

TYPICAL HEAT TREATMENT PROCESSES AT A GLANCE

- Hardening: Heating and rapid quenching (e.g. in oil or water) to increase hardness

- Tempering: After hardening, reheating to reduce brittleness and increase toughness

- Annealing: Slow heating and cooling to reduce stress and adjust the microstructure

- Normalizing: Air-cooled cooling for a uniform grain structure, especially for steel

- Quenching: Rapid cooling for martensite formation and hardening

- Tempering: Combination of hardening and tempering for highly resilient components

Challenges in heat treatment

- Recurring downtime due to manual or error-prone processes

- High personnel deployment in hot weather - increases accident risks and reduces efficiency

- Imprecise processes and reworking jeopardize quality and adherence to deadlines

- Limited scalability due to lack of automation in handling

Reliable material handling for your heat treatment process

Efficient heat treatment starts with precise handling. Our automated handling systems take care of loading, unloading and transport - reliable, temperature-resistant and tailored to your processes. They ensure constant cycle times, greater work safety and reproducible results - even under extreme conditions. This allows you to sustainably increase efficiency, quality and process reliability in industrial heat treatment.

HEAVY-DUTY ROBOT STM 50

The STM 50 rail-mounted heavy-duty robot (SLR series) is designed for gripping, turning, lifting and tilting rings and disks. Its compact design is suitable for confined spaces, while self-centring gripper rollers can flexibly handle different workpiece diameters. A laser sensor enables precise positioning, ideal for heavy-duty applications.

- Load capacity: 5,000 kg (11,000 lbs)

- Gripping technology: Self-centering gripping rollers

- Precision: Laser sensor for exact positioning

- Gripper rotation: Multiple rotation

- Linear movements: Lift and feed mechanisms for fast and precise processes

- Design: Compact construction, heat-protected cable routing, sound insulation thanks to protected housing