![[Translate to Englisch:] Pipe Sizer von DD für die Rohrumfomung](/fileadmin/_processed_/6/8/csm_pipe-sizer-dango-dienenthal_c2346c613d.jpg)

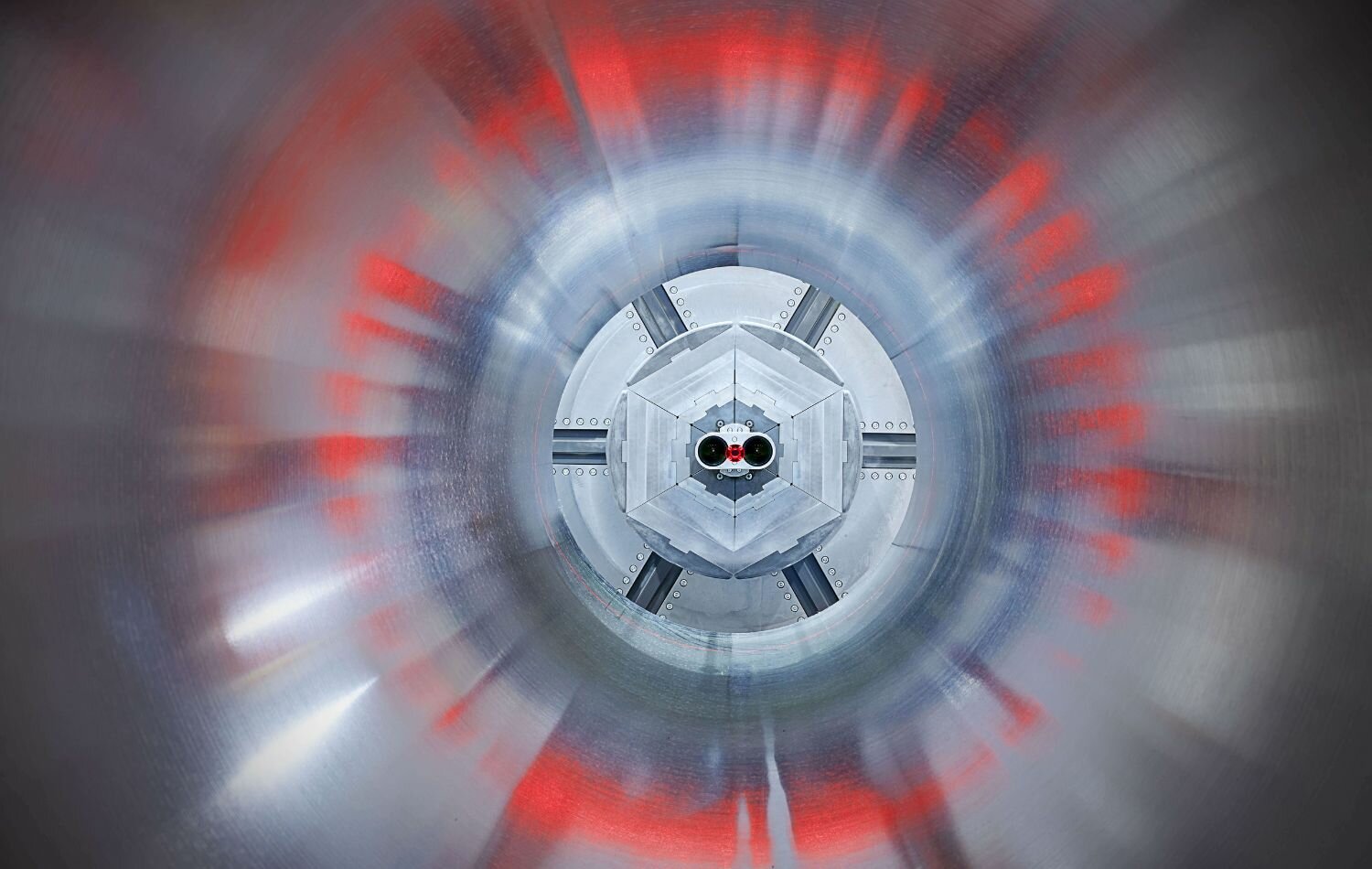

LASER-ASSISTED CALIBRATING

OF LARGE PIPES

The PIPE SIZER is the world's first pipe manufacturing machine to combine high-precision measuring and sizing of pipes in one unit. The 360° laser measuring system measures the pipe's internal geometry with the highest accuracy, while software specially developed for pipe manufacturing calculates the parameters for accurate, controlled sizing of pipes.

With the PIPE SIZER, you can reduce your calibrating time by up to 80%, increase your daily output and revenue by more than three times and achieve your ROI from the very first major order - with maximum precision and quality for the most demanding pipe manufacturing requirements.

![[Translate to Englisch:] Pipe Sizer Rohrenden](/fileadmin/_processed_/f/e/csm_pipe-sizer-rohrenden-0000_855ad32c73.jpg)

Pipe Sizer

in Application

Scope of delivery

- Machine type PST 1300 PE EX with integrated 360° circular laser measuring system for measuring and pinpoint sizing of pipe ends (incl. additional expander function)

- Double unit with two opposing PIPE SIZER units

- System software (PLC software and DDPST software specially tailored by DANGO & DIENENTHAL for the pipe industry)

- Programming of the customer’s pipe guidance and positioning (automatic center point correction)

- One stationary compact hydraulic unit for both machine units

- Tools for flexible use with internal pipe diameters (iØ) from 276 to 1,016 mm

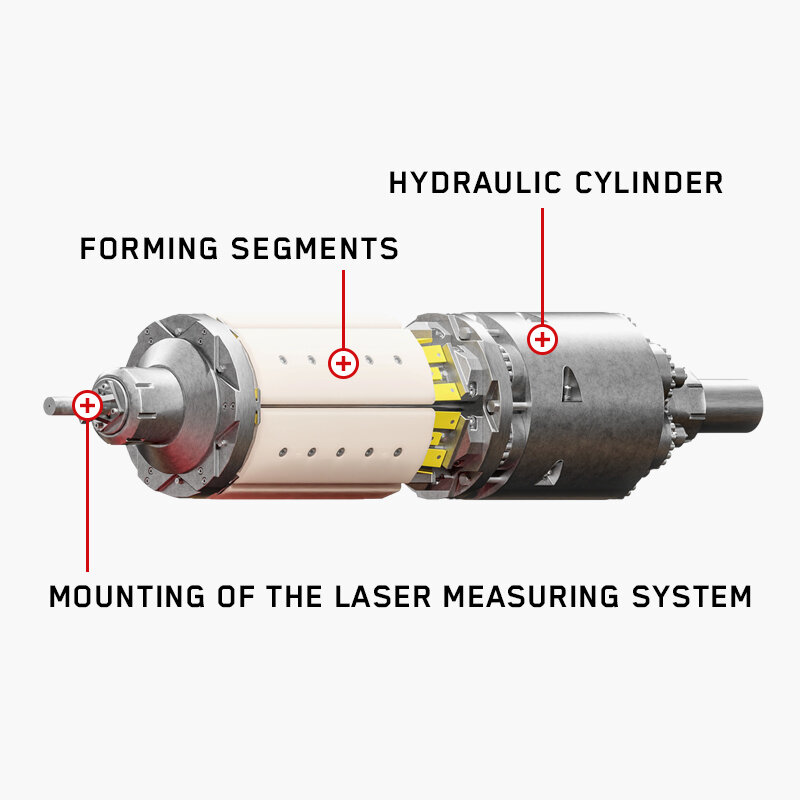

Design and function

of the PIPE SIZER

MEASURING AND SIZING

The 360° circular laser measuring system integrated at the front of the PIPE SIZER is moved into the metal pipe and records the geometry of the inner pipe wall.

The software uses the results to calculate the default values for the forming segments and transmits them to the process control system.

Depending on the position of the smallest internal diameter, the forming segments are then extended to create the desired inner contour.

After completing the first pipe sizing process, the industrial pipe is measured again. Based on the contour data generated, the software calculates the pipe material’s springback value and factors it into the subsequent pipe sizing process. This way, the individual material properties of each metal pipe are utilized for pinpoint calibration.

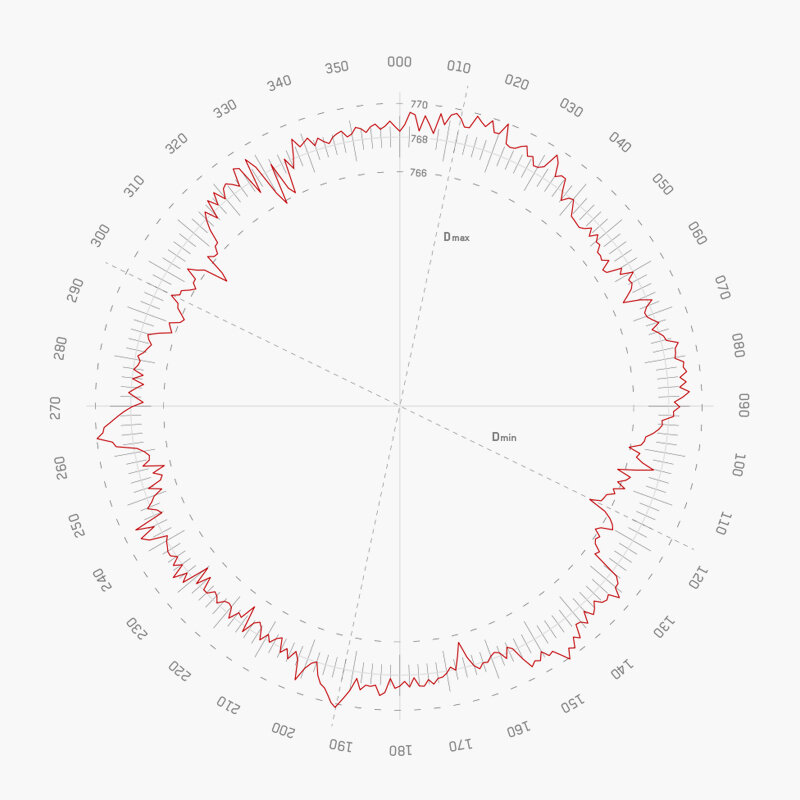

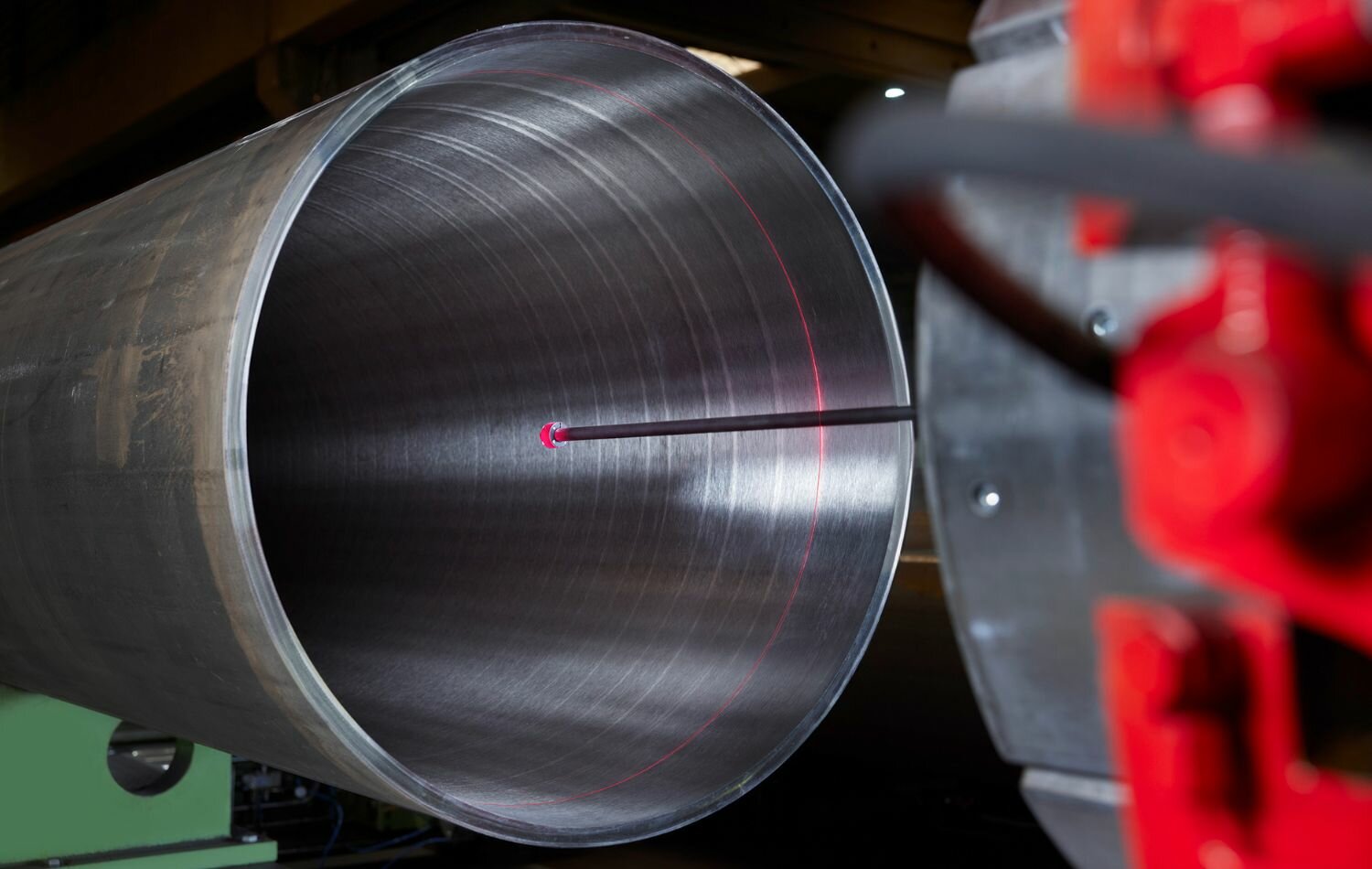

PRECISE INLINE MEASUREMENT

A laser-based optical measuring system is mounted at the tip of the measuring lance. It measures the inner contour of the metal pipe without contact, generating a complete 2D image of the pipe interior at various depths.

The measuring system works on the principle of laser triangulation: the laser projects a line onto the inner wall of the metal pipe. Two cameras contained in the measuring head capture the circular line with up to 1,080 measuring points over the entire circumference of the industrial pipe. This corresponds to an angular resolution of around 0.33°.

The software determines the distance between the pipe axis and the inner pipe wall and uses this to generate the inner contour of the pipe. The 360° circular laser measuring system ensures extremely high repeatability. In addition, the recorded data guarantees full documentation of the entire process.

PINPOINT SIZING

The forming segments of the PIPE SIZER are controlled and spread apart by a hydraulic cylinder in accordance with the pipe geometry.

Depending on the machine model, up to six forming segments are activated, each covering an angle of 60°. If the contour measurement shows that intermediate positions need to be set, the tool carriers can be rotated to the required position thanks to the 360° rotation.

A quick and simple tool change allows flexible use for different pipe diameters.

SPECIALLY DESIGNED FOR THE PIPE INDUSTRY

The software solution developed by DANGO & DIENENTHAL for the 360° circular laser measuring system is specially tailored to the pipe industry.

It includes functions such as automatic center point correction and laser adjustment to the surface characteristics of the inner pipe wall. It also records target, minimum, and maximum diameters as well as ovality. Weld seam masking is also taken into account.

INTERRUPTION-FREE OPERATION

Offline programming enables preparation of upcoming orders, ensuring continuous operation.

SIMPLE DATA EXPORT

All geometric data recorded by the 360° circular laser measuring system is available in TXT, HTML or CSV file format and can be transferred to higher-level systems for the optimization of internal processes. Complete documentation is also ensured.

Pipe kinds

Depending on the design, the PIPE SIZER can be used to size the following types of industrial pipe:

- Linear Pipes

- Pipe Bends

Pipe types

- Longitudinally Welded (LSAW – Longitudinal Submerged Arc Welded)

- Spirally welded (HSAW – Helical Submerged Arc Welded / SSAW – Spiral Submerged Arc Welded)

- Electric Resistance Welded (ERW)

- High-Frequency Welded (HFW)

- Seamless (SMLS)

- Solid Material Pipes

- CRA/Clad Pipes

Internal pipe diameter

- 276-1,016 mm

Maximum efficiency

With a double unit consisting of two opposing PIPE SIZER units, both pipe ends can be measured and then calibrated simultaneously. This not only halves the processing time, but also safes the time otherwise required for turning the pipe.

In addition to the PIPE SIZER, DANGO & DIENENTHAL also supplies a pipe lifting system and the required programming for seamless integration into the production process.

PIPE CALIBRATION WITHOUT PLASTIC DEFORMATION

When calibrating with standard expanders, pipes are subject to plastic deformation.

The PIPE SIZER, on the other hand, sizes the metal pipe interior point by point whereby the average diameter is retained, and the material properties are preserved virtually unchanged.

MINIMUM OVALITY

Ovality is the difference between the largest and smallest diameter in a plane. The higher the roundness requirements, the more precise the measurement has to be.

Using state-of-the-art laser measuring technology, the PIPE SIZER captures the pipe geometry with maximum precision and ensures that quality requirements are reliably met. The PIPE SIZER achieves an ovality of ≤ 2.0 mm.

ADDITIONAL EXPANDER FUNCTION

With the optional expander function, the PIPE SIZER enables gentle pipe expansion – using multi-step tool rotation. The achievable diameter increase is up to 0.8%.

A quick change of tools allows flexible switching between the sizing and expander functions for different pipe diameters.

Downloads

CONTACT

Are you interested in our product?

Then contact us via contact form, contactnoSpam@dango-dienenthalnoSpam.de or +49 271 401 4000.

We look forward to your inquiry!

![[Translate to Englisch:] zusätzliche expander-funktion den pipe sizer](/fileadmin/_processed_/f/f/csm_pipe-sizer-expandieren_a400baff7c.jpg)